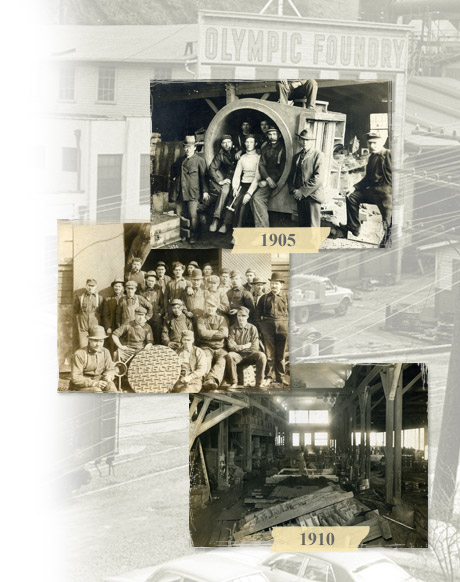

ABOUT US

Olympic Wear, as a division of Olympic Foundry, began manufacturing wear resistant castings for the coal-fired utilities in 1972. Already casting wear items in 28% chrome for the rock crushing industry, Olympic chose not to cast its new product in Ni Hard, the 1970’s industry standard. Recognizing an opportunity for improvement, Olympic instead sized its patterns for 28% chrome. This increased Brinell hardness to the 700 range as opposed to the 550 range of Ni Hard providing longer wear life to the parts.

In 1983 Olympic Wear Company purchased the division from Olympic Foundry. Some of the same personnel remain with Olympic Wear today.

Olympic Wear continues to provide improved alternatives to its customers, working with engineers and pattern makers to modify parts for easier or better use and modifying alloys to improve specific metal characteristics for specific function. Olympic Wear strives to save customers money, provide high quality parts, deliver on time and keep industry in America.